DAS Solar N-type modules gain additional 3.34% of electricity than P-type modules

2023-06-07

Electricity generation directly affects the choice of PV technology route and the customer's product selection. To validate and study the power generation performance of N-type modules, DAS Solar has partnered with TÜV SÜD to conduct a one-year outdoor validation project at the base of China Building Material Test & Certification Group Co., Ltd. (hereinafter referred to as "CTC") from January 2023 to December 2023. Also, DAS Solar has completed four months of data analysis and testing reports, spanning from January 2023 to April 2023. This article aims to analyze the electricity generation data and features of N-type products.

Rigorous test design

The validation site is located in Ding'an County, Hainan Province (latitude: 19°40', longitude: 110°18'). The average annual temperature is 24°C, with an average relative humidity of over 90%. There are approximately 1880 hours of annual sunlight, with an average annual peak sun hours (PSH) of around 1600 hours. The average annual precipitation is 1953 millimeters, with the rainy season (May to October) experiencing an average rainfall of 1594.4mm. The annual ultraviolet (UVA and UVB) radiation accounts for approximately 5.6% of the total radiation.

N-type TOPCon modules

P-type PERC modules

The PV plant has installed a matrix of N-type bifacial modules (using DAS Solar N-type TOPCon modules) and a matrix of P-type PERC bifacial modules, each with an installed capacity of approximately 5 kW (both N-type and P-type modules consisting of 9 pieces per matrix). These modules are connected to string inverters (SUN2000-60KTL) for grid-connected power generation. The project utilizes an adjustable fixed mounting structure with a tilt angle of 16 ℃, no rear shading, and the ground surface is covered with grass. The modules are installed at a minimum height of around 1 meter above the ground. Apart from the installation of a site-level environmental monitoring station, the site also features high-precision DC meters, module-level temperature sensors, and front and rear irradiance sensors for monitoring purposes.

The power generation capacity of photovoltaic modules depends on power degradation, high-temperature performance, bifacial power generation performance, and low irradiance performance. In the testing conducted at this PV plant, both the N-type and P-type modules have been adopted with the same module packaging format. The performance differences in power generation mainly arise from variations in module performance resulting from different cell technologies. Additionally, to ensure precise data and eliminate the influence of inverters on the power generation performance of different module types, direct current meter data is directly employed for system design and module power generation analysis, with normalization processing applied.

Low power degradation, low temperature coefficient, and high bifaciality

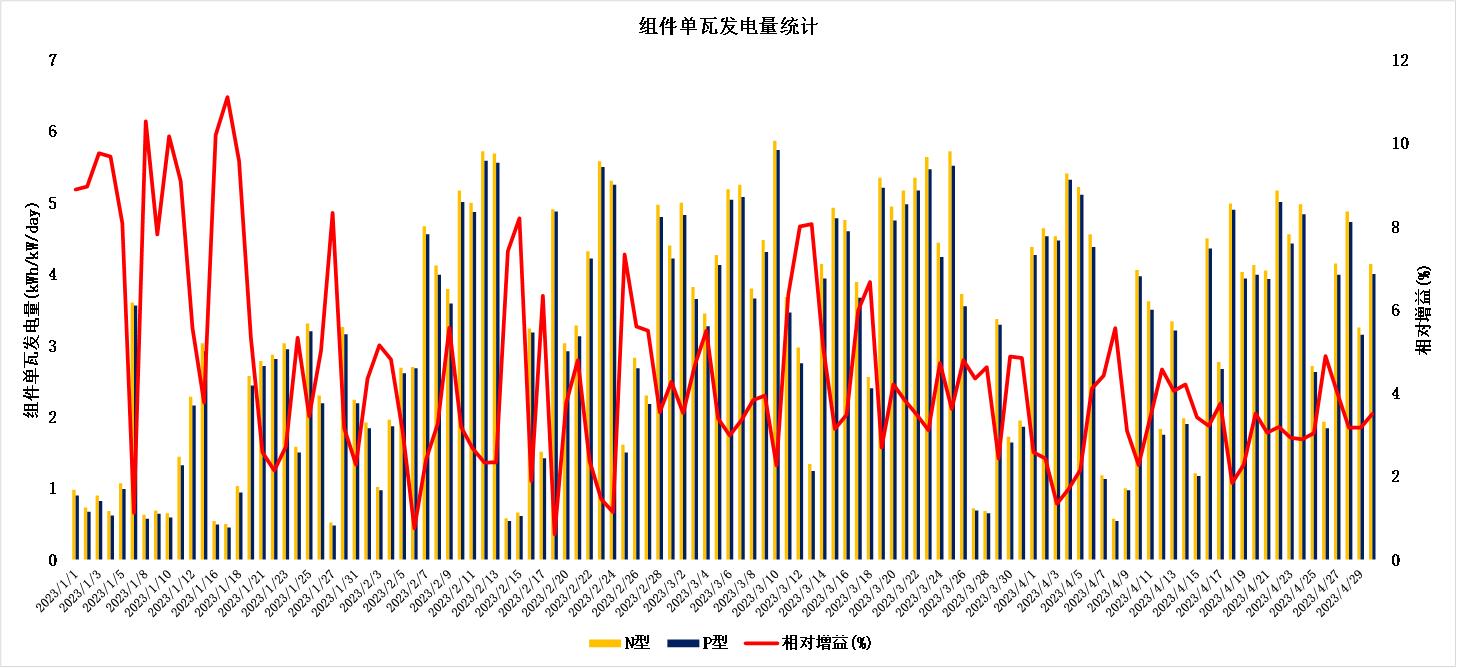

According to data from January 2023 to April 2023, the graph indicated that the average daily power generation per watt for the two types of modules is 3.40 kWh/kW and 3.29 kWh/kW, respectively. The power generation per watt of N-type modules is approximately 3.34% higher than that of P-type modules. N-type modules have lower power degradation and temperature coefficient. Therefore, as the ambient temperature rises and time passes, the power generation of N-type modules increases gradually.

Comparison data of watt-level power generation for N-type and P-type modules

N-type technology has the advantage of power degradation performance without B-O complex). The N-type module exhibits a first-year degradation of 1% and an annual linear degradation of 0.4%. In contrast, the P-type module has a first-year degradation of 2% and an annual degradation rate of 0.45%.

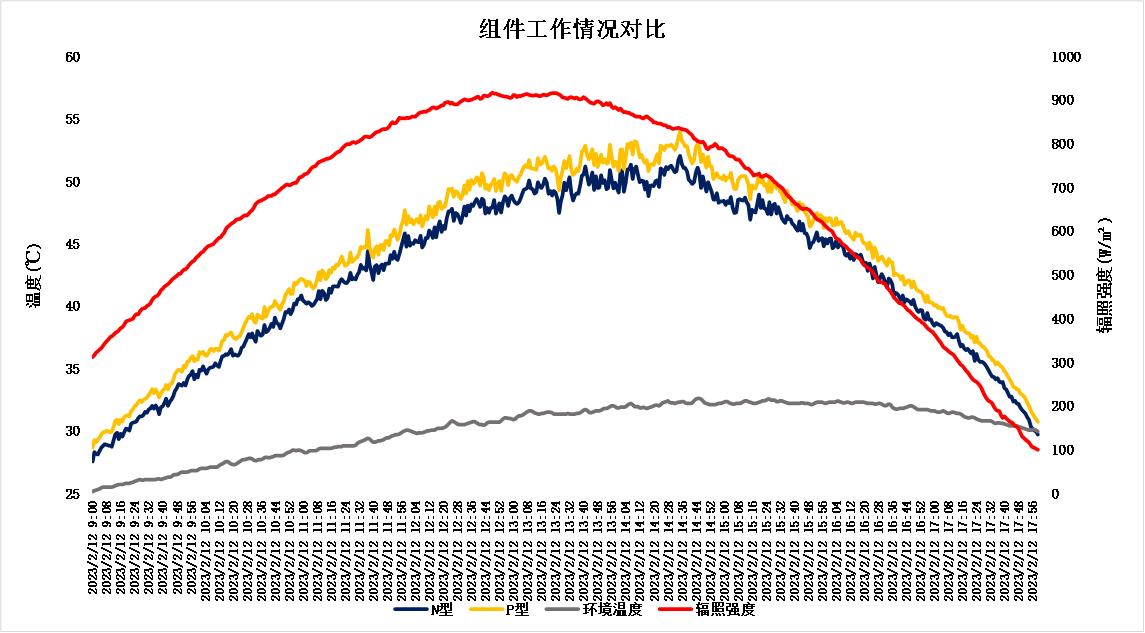

The high-temperature power generation performance of the modules is closely related to the module temperature coefficient and operating temperature. In theory, a higher open-circuit voltage of the cell and a more favorable temperature coefficient are desired. For instance, the DAS Solar TOPCon cell achieves an open-circuit voltage of 720mV, with a module temperature coefficient of -0.30% per degree celsius, while the P-type module has a temperature coefficient of -0.34% per degree celsius. Under high-temperature conditions during summer, the N-type module's advantage in high-temperature power generation becomes more pronounced. Additionally, due to its higher conversion efficiency, the N-type module reduces the thermal conversion of absorbed light energy, thereby lowering the module's operating temperature. This empirical project also effectively validates this point, with the N-type modules exhibiting an average temperature approximately 1.6°C lower than the P-type modules, as shown in the diagram below.

Operating temperature comparison data for N-type and P-type modules

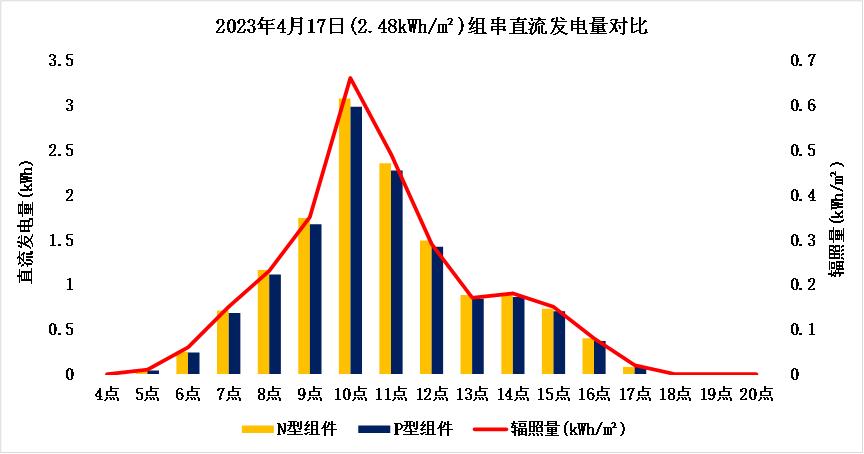

The technology of DAS Solar TOPCon cell incorporates three innovative techniques: the high-energy laser-induced selective emitter (i-SE), ultra-thin polycrystalline silicon with micro-doped untrap poly-Si (ut-polySi), and emitter stack surface passivation (mt-Pass). These advancements enable the N-type modules to achieve a bifacial rate of up to 80%, while the P-type modules only achieve around 70% bifaciality. Furthermore, in theory, the low irradiance power generation performance of the modules is closely related to carrier lifetime, open-circuit voltage, and shunt resistance. Under weather conditions such as cloudy or rainy days, the N-type modules exhibit superior power generation compared to the P-type modules, as shown in the diagram below.

Comparative power generation data of N-module and P-module (under low irradiation environment)

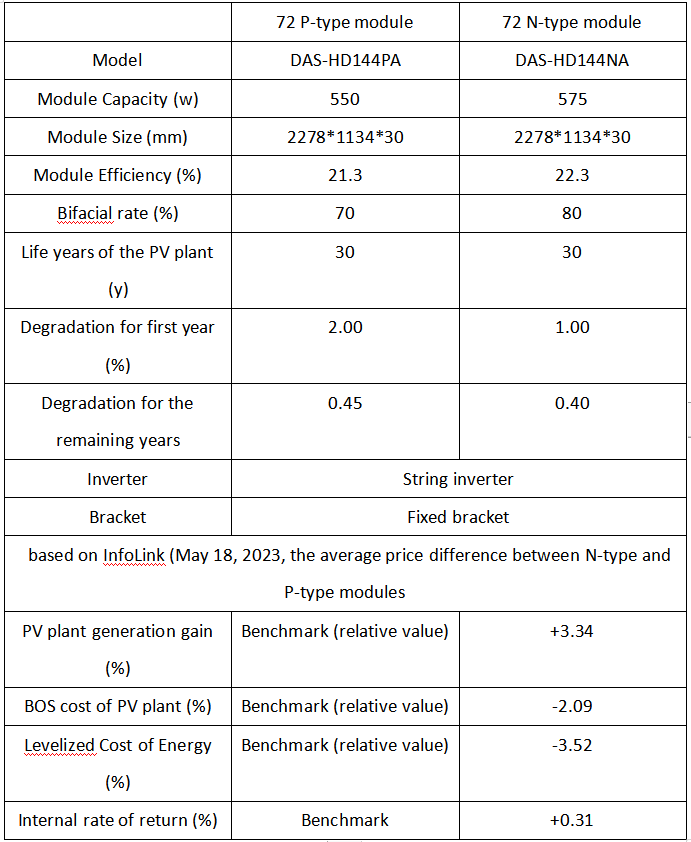

N-type delivering higher profit

Based on the data calculation showing a 3.34% higher wattage per unit for N-type modules compared to P-type modules, in the same geographic location (Haikou, Hainan, Class II light resource area) for constructing PV plants. Assuming that the PV plant systems adopt the same design logic and have consistent DC capacity (100MW on the DC side), the profitability data calculation is based on InfoLink (May 18, 2023, the average price difference between N-type and P-type modules) shown below.

Based on the data presented in the above graph, it can be inferred that the PV plant cost for N-type modules of the same type is lower compared to P-type modules, while the profitability is higher. This is due to the high power output, excellent power generation performance, and low degradation exhibited by N-type modules (peak power temperature coefficient of -0.300% per degree celsius, first-year degradation of 1%, and linear degradation of 0.40%). These factors contribute to a shorter project investment payback period and effectively reduce the cost of electricity. Furthermore, as N-type technology continues to be industrialized, the cost difference between N-type and P-type is gradually narrowing, thereby amplifying the advantages of N-type in the future.

In conclusion, during the period from January 2023 to April 2023, the TÜV SÜD certified PV plant, which utilized DAS Solar N-type modules, exhibited a wattage per unit power generation that was approximately 3.34% higher than that of P-type modules. This highlights the pronounced power generation advantage of N-type modules and provides substantial.

*The above data is from TÜV SÜD Hainan PV plant

浙公网安备33080302000236

浙公网安备33080302000236