DAS Solar is a leading high-efficiency N-type silicon cell and module manufacturer in China. Founded in 2018, DAS Solar took the lead in establishing China's first 1.2 GW/y production line of high-efficiency TOPCon cells, which filled an industry gap. Through continuous scientific and technological innovation, DAS Solar has enhanced the presence in the N-type cell industry. The laboratory efficiency of the N-type TOPCon cells has exceeded 26%. The efficiency of the cells will be raised to 26% by developing passivation contact technology and improving the carrier selection rate. The perovskite/silicon tandem cell technology under development will break the theoretical limit (29.4%) of crystalline silicon cells, and the industrialized cell efficiency will exceed 32%.

Technology R&D

Leading the N-Era

Seven major innovations

for efficiency improvement

-

The application of the cutting-edge high-efficiency

The application of the cutting-edge high-efficiency passivation contact technology and the updated application of a laminated nano-tunneling oxide layer and carrier selectivity transmission layer have solved the technical challenges that conductivity and passivation cannot be enhanced at the same time. The resulting enhancement of passivation and conductivity has dramatically improved cell conversion efficiency.

-

Gradient dielectric film technology is applied to the front faces of cells for passivation

Gradient dielectric film technology is applied to the front faces of cells for passivation, anti-reflection and extinction, and resistance to PID. Furthermore, this technology prevents cell color change upon lamination, which ensures a consistent color of cells and uniform and attractive module appearance.

-

Ultra-thin polysilicon technology

Ultra-thin polysilicon technology is used to minimize the parasitic absorption of incident light with a long wavelength by polysilicon, and to remarkably enhance current density. The back is designed with stepped three-dimensional morphology to improve internal reflection, ameliorate metal contact properties on the back, and enhance the cell efficiency and bifaciality.

-

A new edge passivation technology

A new edge passivation technology and special field effect passivation materials are used to treat cell sides, repair the passivation layer after cell cracking, and then passivate the side defects to minimize cell cracking-induced efficiency loss.

-

SMBB metallization technology

SMBB metallization technology and finer grid lines are used to reduce occlusion and conduction distance. This technology has effectively reduced series resistance and improved the resistance to hidden cracks, grid breakage, and rupture in cells, thereby improving the reliability.

-

Nondestructive cell cutting technology

Nondestructive cell cutting technology is used to avoid mechanical damage, yield high efficiency, and reduce pollution; it is also compatible with 166/182/210 mm large-size cells.

-

Half-cell technology

Half-cell technology is used to halve the current, reduce resistance, increase cell spacing, and achieve uniform reflection. The hot spot temperature of half-cell modules is 20°C lower than that of full-cell modules. SMBB technology is used with round wire solder strips to enhance the utilization of incident light by 70%, which contributes to a power ascension of 1-1.5%.

High-efficiency Modules

with Better Performance

More Competitive

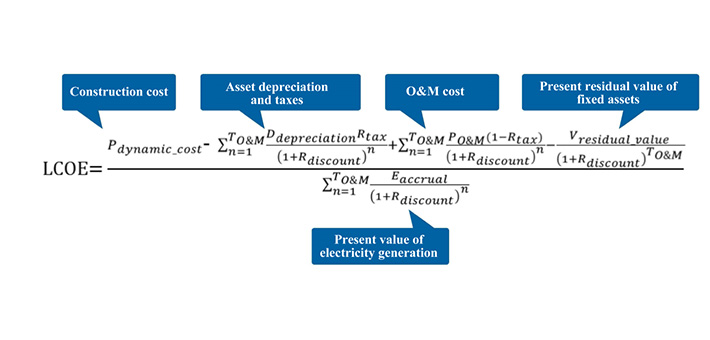

Systems for Lower LCOE

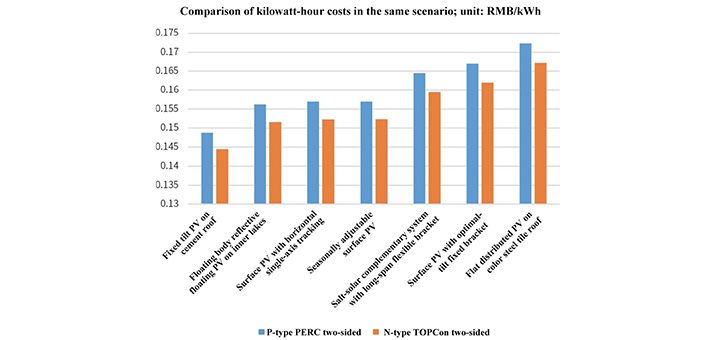

By virtue of the high-efficiency N-type cells, DAS Solar has developed three series of high-efficiency N-type products with full power coverage under the DAON brand, to exhibit its latest strength in innovation, module R&D, and mass production of high-efficiency N-type cells. Benefiting from the lower power attenuation, higher bifaciality, low temperature coefficient, and increased low irradiation performance of N-type modules, DAON N-type modules can generate up to 5% more power than P-type modules at the same installed capacity, thereby significantly reducing the kilowatt-hour cost of PV systems and the earning rate of PV power plants.

DAS Solar developed PV systems with flexible bracket, amphibious PV systems, floating PV systems, PV energy storage, charging integrated parking lots, and other applications. DAS Solar's DAON N-type products (PV system with flexible bracket) exhibit obvious superiorities in PV sand control, offshore wind-solar combined farm, expressway slope PV, and other new applications.

The analysis of such strengths as integrated solar-electric energy conversion efficiency, bifaciality, annual decay rate, temperature coefficient, low light responsiveness, hot spot effects, low risk of hidden cracks, and BOS system cost sharing, for various applications revealed that DAON N-type products have obvious superiorities in kilowatt-hour costs.

Adhering to a technology leading strategy, DAS Solar has been committed to offering green products with high quality, high efficiency, and high reliability. DAS Solar has constantly improved cell and module efficiency by means of overlaying large silicon wafers, passivation contact technology, gradient film technology, ultra-thin polysilicon technology, edge passivation technology, multi-main grid technology, half-cell technology, and other cutting-edge packaging technologies.

浙公网安备33080302000236

浙公网安备33080302000236